Inside the Craft: How Daxin Glass Elevates Fragrance Packaging Through Design and Precision

Inside the Craft: How Daxin Glass Elevates Fragrance Packaging Through Design and Precision

Date: 21 - 23 April, 2025

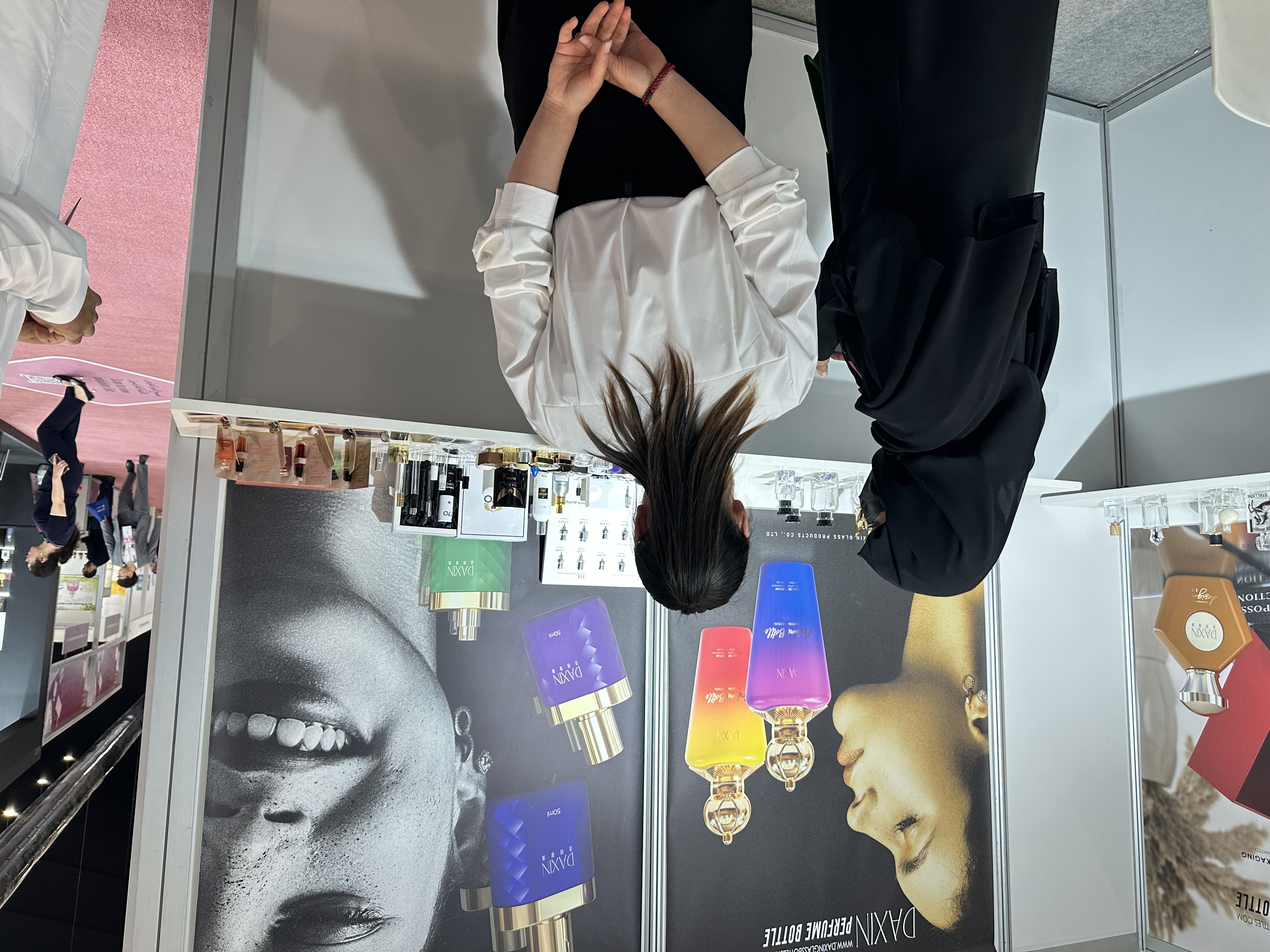

In the world of luxury fragrance, packaging is more than protection—it's performance, identity, and artistry combined. At Beautyworld Saudi Arabia 2025, few brands captured this truth as clearly as Daxin Glass. Known for its meticulous craftsmanship and consistent quality, Daxin Glass gave attendees a rare glimpse into the intricate process behind some of the industry's most admired perfume and aromatherapy packaging.

While consumers often fall in love with the final product—the sparkle of glass, the weight of a cap, the elegance of a form—what lies beneath that beauty is years of technical refinement, material understanding, and collaborative design.

A Foundation of Excellence

With decades of experience in the glass packaging industry, Daxin Glass has established itself as a trusted partner to fragrance and wellness brands across the globe. Their core offerings—perfume bottles, aromatherapy bottles, 2ml sample perfume bottles, and zinc alloy lids—are united by a single principle: precision.

This precision begins long before a bottle reaches the shelf. From raw materials to mold design, from temperature control to hand finishing, Daxin's team is involved at every step, ensuring the final product reflects the high standards of both the company and its clients.

The Art and Science of Glassmaking

Creating a high-quality glass bottle is a delicate balance of science and design. Each bottle must be visually flawless and physically durable—capable of withstanding production lines, transportation, and long-term consumer use.

At Daxin's manufacturing facilities, premium raw materials are carefully selected for clarity, purity, and consistency. These include sand, soda ash, and limestone—combined in exact proportions to ensure stable glass formation.

Once melted, the molten glass is poured into precision-engineered molds, designed either in-house or to client specification. Temperature is tightly controlled at every stage to prevent defects like bubbles, warping, or uneven thickness. After molding, bottles pass through annealing ovens to relieve internal stress, ensuring long-term structural integrity.

Finally, bottles are cooled and subjected to rigorous inspection—both by machine and by trained technicians. Minor surface flaws, irregular thickness, or shape variations are flagged and removed before finishing.

Mastering the Small Scale: 2ml Sample Bottles

While large bottles get the spotlight, 2ml sample perfume bottles present some of the greatest challenges in manufacturing. Their small size means that even a fraction of a millimeter in discrepancy can affect functionality—especially when paired with fine atomizers or droppers.

Daxin Glass applies the same high standards to its miniature formats as it does to full-size offerings. These samples are designed for precision dispensing, leak prevention, and visual appeal—often used in promotional kits or luxury discovery sets.

At Beautyworld Saudi Arabia, many attendees were surprised by the level of detail in these tiny bottles. Polished bases, uniform neck finishes, and optional surface decoration demonstrated that Daxin's attention to craft does not diminish with size.

Aromatherapy Bottles: A Balance of Form and Function

The aromatherapy market demands packaging that feels calming, natural, and premium. Daxin Glass designs its aromatherapy bottles to suit a wide range of applications—from essential oil blends to room sprays and spa products.

These bottles must be compatible with different closures—droppers, pump sprayers, screw caps—while maintaining tight seals and precise dispensing. The glass must also protect sensitive formulas from light and oxidation, which is why many aromatherapy bottles are offered in amber or frosted finishes.

Design-wise, Daxin offers options that range from minimalist to ornate. Some clients choose to incorporate engraved logos, textured surfaces, or custom color gradients—each crafted with care to preserve both function and identity.

Zinc Alloy Lids: Where Engineering Meets Luxury

Fragrance caps are often underestimated, but in truth, they can make or break a product's tactile impression. Daxin Glass offers a range of zinc alloy lids that combine durability with luxury.

Unlike plastic caps, zinc alloy allows for greater weight, metallic shine, and shape complexity. These caps can be plated in gold, chrome, matte black, or rose finishes, among others, and customized with embossing, enamel inlays, or decorative stones.

Precision engineering ensures that each lid fits its bottle snugly, maintaining a satisfying closure that signals luxury to the user. In an industry where details matter, Daxin's lids elevate the entire product experience.

A Culture of Quality Control

Every step in Daxin Glass's production process is monitored by an internal quality team. From dimensional measurement tools to visual inspections under high-powered lighting, the goal is simple: only flawless components move forward.

For customized orders, the company maintains a sampling and approval process, allowing clients to physically review prototypes before mass production. This ensures alignment on dimensions, color, fit, and finishing.

Moreover, Daxin's technical staff regularly audits equipment and retrains personnel to uphold manufacturing standards. It's a system built not just to catch problems, but to prevent them entirely.

Collaboration as a Core Strength

One of Daxin Glass's biggest advantages is its client collaboration model. Whether a brand is launching its first fragrance or managing a global portfolio, Daxin's team engages directly with their creative, marketing, and supply chain departments to create tailored solutions.

From initial sketches to material selection and finishing recommendations, Daxin's engineers and designers contribute practical insights that help balance aesthetics with feasibility.

At Beautyworld, the company highlighted several case studies where joint development led to breakthrough products. One such project involved designing a bottle with interchangeable zinc caps for seasonal fragrance collections. Another centered around crafting a limited-edition sample bottle with a mirrored inner surface—an ambitious idea that Daxin brought to life using proprietary coatings.

The Beautyworld Experience

Beautyworld Saudi Arabia 2025 provided a platform for Daxin to showcase not just products, but process. Attendees were invited to touch, test, and examine the latest packaging solutions—experiencing firsthand the precision that defines every Daxin bottle and cap.

Among the most discussed displays:

1. A new line of weighty square perfume bottles with polished zinc alloy caps

2. Gradient-colored aromatherapy bottles with matching droppers

3. Miniature sample kits designed for premium gifting

4. Behind-the-scenes visuals of the Daxin production process

Industry professionals expressed particular interest in the company's ability to meet low minimum order quantities for custom work—a key need for niche and indie brands.

Looking to the Future

As the fragrance industry continues to evolve, Daxin Glass is investing in both automation and artisanal techniques to stay ahead. Future plans include:

1. Advanced mold-making for more complex bottle shapes

2. UV-curable decoration methods for faster lead times

3. Hybrid caps combining metal and sustainable materials

4. Expansion of services in the Middle East and North Africa (MENA) region

Daxin is also exploring the integration of QR-embedded packaging, allowing consumers to access authenticity information or brand stories through a simple scan—a perfect intersection of digital and physical experience.

Conclusion: Why Craft Matters

In the end, it's not just about creating a beautiful bottle or a sturdy cap. It's about making packaging that reflects the soul of the brand—consistently, precisely, and elegantly. Daxin Glass achieves this by honoring the craft behind every detail, no matter how small.

Whether it's a 2ml sampler or a signature bottle that defines a brand's image, Daxin approaches each project with the same level of commitment. At Beautyworld Saudi Arabia 2025, this dedication shone through—making clear that when it comes to perfume packaging, craftsmanship isn't an extra. It's the standard.